For General Contractors & Installers

Proudly made 100% in the USA

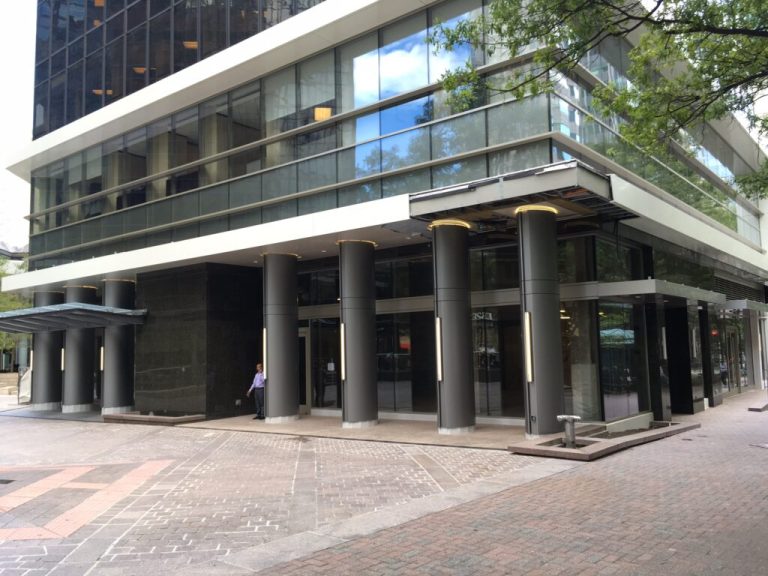

We are always excited to host you here in Marble Falls, TX to tour our factory, see how the product is made and actually put it on the wall in our interactive installation training facility.

Contact us at [email protected] to set up your visit.

General Contractor Partners

Installation Partners

Why SPI?

We Provide Quality Products on Time

Our complete system arrives ready to install with a fully engineered set of shop drawings, where each piece is uniquely identified. Corners are fabricated to look monolithic, clips are located and installed requiring no additional onsite fabrication and minimal field cutting for wall penetrations. All of these features lead up to a faster install time and helping to control costs.

Frequently Asked Questions

SPI has invested well over $2 million in independent laboratory testing ranging from accelerated aging all the way through various types of structural, fire, blast loading, and air/water infiltration testing to be certain that the system will perform under all conditions and in all climates.

Stone Panels International LLC is the only lightweight stone supplier accepted (approved) by the International Code Council (ICC), the building authority who writes and administers the model code for all construction in the U.S. and many other countries. The ICC-Evaluation Service has accelerated aging, structural and impact, fire, plus air and water infiltration requirements which must be met for products and systems to gain acceptance.

Stone Panels International LLC is the only U.S. manufacturer of lightweight natural stone composite panels accepted (approved) by the Miami-Dade County Building Code Compliance Office. That organization is responsible for evaluating exterior wall systems and testing for proof of ability to resist hurricane wind and large missile impact.

Ongoing quality control procedures are monitored by the ICC, the Miami-Dade NOA Compliance office, the British Board of Agrèment in the UK, and the Avis Technique in France. Stone Panels International LLC is the only U.S. building products manufacturer accepted by the Avis Technique. This testing, quality control, and building official acceptance assures the design-build community that they are buying a system that will perform for many years.

StoneLite® panels use about 1/3 the amount of stone that is required for traditional stone cladding. Quarrying and transportation of dimensional stone requires a great deal of energy so the ability to harvest significantly less stone not only saves energy but also leaves more natural resources intact for future use.

At only 3.5 lbs. per sq.ft. and an allowable deflection of more than L/120, StoneLite® panels require less structural steel and concrete back-up as it can be installed over steel stud framing. Less structural steel and less concrete reduces the energy required for manufacturing and transportation and ultimately requires fewer natural resources.

Because of the light weight of the material, furring can be added to create a cavity for exterior insulation which will increase energy efficiency of the building. Mechanical contractors usually employ energy modeling software and can evaluate the long term energy savings based on this type of envelope design. Smaller and fewer attachment points also reduce thermal bridging and increase energy efficiency whether the insulation is placed inside the wall cavity or on the exterior.

StoneLite® panels are suitable for rainscreen or open joint applications. Rainscreen is particularly advantageous in climates where the temperature differential between interior air and exterior is high because it allows the wall system to dry out, eliminating the environmental conditions that support the growth of mold. In fact, the highest mold litigation state in the country is Arizona because of the cooler air inside the building and the hot air outside. This temperature differential combined with tightly sealed wall systems can produce a condensation point within the wall and support mold growth. Generally a minimum air gap of 1″ is required to provide adequate ventilation.

Almost any stone can be incorporated in the panel system. This allows the possible benefit of regional materials credit if attention is paid to the selection of stone that is quarried within 500 miles of the project location.

The specifications can be found on our website under the Specifications tab. The specifications are offered in two formats – pdf and Word. Word allows the specifier to create a project-specific specification.

Stone Panels International LLC normally supplies painted interlocking channel (ILC) aluminum extrusions for all installations in the US. The paint works as an insulator to prevent electrolytic action between aluminum and other materials including steel. Self-drilling, self-tapping screws (supplied by others) are used for attaching ILCs to back-up framing. SPI recommends attachment of ILCs using neoprene washer head fasteners to prevent direct contact between a steel screw and the aluminum. SPI recommends corrosion resistant screws.

Anodized aluminum ILCs are typically supplied for rainscreen installations in Europe and Canada.